proyectos Meulage de pierre roca

-

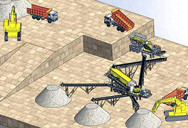

gravier concasseurs convoyeurs

-

barytine au nigeria

-

fournisseur de la plaque de concasseur a machoires en Indel'impact

-

broyeur Indonésie boulets broyeur pour la pierre

-

broyeur de pierres pub

-

concasseur plan d

Cement - Extraction, Processing, Manufacturing Britannica

cement - Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as

Bavarder sur Internet

Cement Manufacturing Process Phases Flow

2012年8月30日 Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six

Bavarder sur Internet

Manufacture of Portland Cement- Materials and

Manufacture Process of Cement The manufacture procedures of Portland cement is described below. Mixing of raw material Burning Grinding

Bavarder sur Internet

2 Types of Manufacturing of Cement - Wet and Dry Process

2023年4月11日 Manufacturing of cement is a process that involves several steps, from extracting raw materials to packaging and shipping the final product. In this blog post, we

Bavarder sur Internet

Cement Production Process Cement Manufacturing Process AGICO CEMENT

2020年8月25日 How much do you know about cement production process? A full cement production process includes the cement crushing process, raw mill process, clinker

Bavarder sur Internet

Cement Manufacturing Process: 6 StepsTo Make

2020年1月27日 In the real cement production line, we detail the cement manufacturing process in six steps, including crushing, raw meal grinding, homogenization, preheating and clinker production, cement grinding,

Bavarder sur Internet

Cement Manufacturing Process: What is Cement

2 天之前 Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of

Bavarder sur Internet

Manufacturing of Cement By Dry and Wet Process - Expert

The cement is manufactured by the following procedure:- Mixing of Raw Materials: In the wet process, there are two raw materials e. calcareous and argillaceous. Initially, Calcareous

Bavarder sur Internet

2 Process Of Manufacture Of Cement - Civil Giant

Various stages of manufacturing of cement by dry process are described below: 1. Crushing Storage The limestone and clay are ground separately to a size of about 25 mm in crushers. Then it is pulverized into fine

Bavarder sur Internet

Three Quick Tips For Manufacturing Of Cement Building

2017年10月3日 Manufacturing Of Cement. by any one of the two methods : (i) Dry process, and (ii) Wet process. In both these processes the three distinct operations of (a) Mixing, Ball mill (b) Burning, Rotary kiln and (c) Grinding are carried out. 1. Dry process.

Bavarder sur Internet

Concrete Production, Placement, Curing Process Summary

2021年1月18日 Curing of concrete is defined as a process to maintain temperature and moisture of concrete during the hydration process of cement due to that hydration of cement completed and concrete gains maximum strength. Curing of concrete done by various methods that are given below. Water curing. Membrane curing. Steam curing.

Bavarder sur Internet

Process of Manufacturing of Cement - Cement - Vincivilworld

2022年9月25日 Stage 1 – Cement Manufacturing process – Raw material Extraction. Limestone is a major raw material used in the cement manufacturing process. Cement manufacturing plants are located near limestone sources for convenient access to raw materials; otherwise, transporting resources from outside would be costly. The next

Bavarder sur Internet

Cement - IEA - International Energy Agency

1 Emissions from manufacturing clinker – the main component of cement – result from chemical reactions and fuel combustion in the process. Measures to reduce emissions include reduction of the clinker-to-cement ratio through the adoption of supplementary cement materials (SCMs), adoption of low-carbon fuels, and capture of residual CO 2 ...

Bavarder sur Internet

Toward electrochemical synthesis of cement—An

2019年9月16日 Portland cement is the most widely produced man-made material in the world, produced at a rate of 4 billion metric tons per year ().Excluding agriculture, cement production is the largest industrial source of greenhouse gases (steelmaking follows closely), accountable today for 8% of global greenhouse gas emissions ().About one-half of the

Bavarder sur Internet

(PDF) THE CEMENT MANUFACTURING PROCESS

THE CEMENT MANUFACTURING PROCESS Prof. Dr Elshafie Ahmed Gad Faculty of Applied Science Chemistry Dept. Portland Cement Portland cement is made by mixing substances containing CaCO3 with substances containing SiO2, Al2O3, Fe2O3 and heating them to a clinker which is subsequently ground to powder and mixed with 2-6 % gypsum

Bavarder sur Internet

Modernizing cement manufacturing in China leads to

2022年11月17日 The cement manufacturing process mainly includes four steps: resource extraction, raw material preparation, clinker calcination, cement grinding 17,18, and fossil fuel burning 19.

Bavarder sur Internet

Manufacturing of Concrete - Civil Wale

2023年7月11日 The manufacturing of concrete is broadly carried in six steps, which when sequentially followed, will produce a properly proportioned and complete mixed ... So, in other words, curing is the process of making the concrete warm and moist enough so that hydration of cement can continue. There are different types of curing, but the most

Bavarder sur Internet

How is Cement Made? [2023] - Specifier Australia

1 The manufacturing process of making cement is a sequence of steps in a manufacturing plant known as cement mills. The basic ingredients for making cement are limestone and clay. These raw materials are mixed with water and ground using milling equipment known as a ball mill to form a slurry. This slurry is then mixed with gypsum in

Bavarder sur Internet

Cement Manufacturing Process: What is Cement

2 天之前 Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method). 1.

Bavarder sur Internet

What Are The Manufacturing Process Of Concrete Process

2 天之前 MANUFACTURING OF CONCRETE. While manufacturing concrete, it should be ensured that every batch of concrete has the same proportions. This is a mandatory requirement so as to satisfy two aspects, viz., same workability and uniform strength. In the manufacturing of concrete the following steps are followed: 1. Proportioning of concrete. 2.

Bavarder sur Internet

Cement Manufacturing Process - Chemical Engineering World

2020年9月26日 Cement Manufacturing Process. Cement Manufacturing Process. Cement is a material which is used to bind other materials together. Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent. Cement is usually not used on its own; it is mixed

Bavarder sur Internet

Cement Manufacturing Process: How the Cement is Made?

2023年7月19日 The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production. The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum

Bavarder sur Internet

Manufacturing of Cement By Dry and Wet Process - Expert

Cement Manufacturing Process Flow Chart. (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in slurry form is directly fed into the kiln which has more amount of water. As shown in the figure it is the upper portion of the kiln.

Bavarder sur Internet

Process of Manufacturing of Cement - Learning Civil

The cement is manufactured by integrating the calcareous component and argillaceous component in a ratio of 3:1. The calcareous component can be limestone, chalk, marine shells, marl whereas argillaceous components can be shale, clay, blast furnace slag, slate. The Calcareous component is used to derive the ingredient called lime whereas the ...

Bavarder sur Internet

Concrete: Manufacturing Process - BrainKart

Concrete: Manufacturing Process . A good quality concrete is essentially a homogeneous mixture of cement, coarse and fine aggregates and water which consolidates into a hard mass due to chemical action between the cement and water. Each of the four constituents has a specific function. The coarser aggregate acts as a filler.

Bavarder sur Internet

Cement Production: How Cement Is Manufactured CEMEX UK

How Cement Is Made. 1. Mining the raw material. Limestone and clay are blasted from rock quarries by boring the rock and setting off explosives with a negligible impact of the environment, due to the modern technology employed. 2. Transporting the raw material.

Bavarder sur Internet

Cement manufacturing process: Step-by-step guide

2020年7月20日 Step 3: Grinding,homogenization and Clinkerization. Next in cement manufacturing process, the crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kiln.A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some

Bavarder sur Internet

Cement Production Process Cement Manufacturing Process AGICO CEMENT

2020年8月25日 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker. Grate cooler helps to cooler clinker, the cooled clinker is sent to the cement silo for storage.

Bavarder sur Internet

Articles liés

- concasseurs de refroidissement de cône d huile

- Fabricants en Nouvelle Caldonia Còne De Concassage

- broyeur Indonésie gypse utilisé

- remercier un oficiel pour une invitation

- impact de masse concasseur

- cylindrique capacite de broyage de la machine produits

- usine concasseur kw mobiles

- béton refroidisseur de l'utilisé de traitement par lots à vendre

- Sénégal utilisée dans le traitement de la bauxite

- spécification de concasseur mobile br

- broyeur rihno rouge à vendre

- concasseur à marteaux conception de dépoussiérage de lusine

- les carrières de pierre calcaire

- Aperçu de flottaison manganèse

- concasseur de pierre erquipment a sable stone quarry

- petites barres métalliques que les concasseurs

- hammer de piedra Meulage de pierre de venta bolivia

- sacc ltd nigeria pierre carrière

- Lignite Équipements De Concassage

- fabricant de concasseur a machoires marshall

- cuesta arena y la industria de la minería de grava en el perú

- co251t de production de lusine de broyage feldsphar

- sistema de lubricasion de farval de molinos

- machine de traitement du gravier

- enlè;vement de soufre en fonte

- concasseur Indonésie cône xl

- Configuration Jsa Plante Rocher De Concasseur

- Moulin Indonésie Charbon Raymond 533

- Livre Optimisation De Broyeur A Boulets

- aluminio electrico puede trituradora