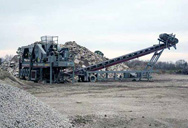

fabricant broyeur concasseur

-

piste hydraulique usine mobile usine india

-

concasseur giratoire principlesand usine de fabrication

-

des broyeurs à boulets calcite

-

Machine De Pulvérisation Catapillar

-

détails de concassage d'agrégats

-

procédure de nettoyage pour des broyeurs Indonésie rouleaux

(PDF) Grinding in Ball Mills: Modeling and Process Control

PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding

Bavarder sur Internet

The Common Feeding Methods of Wet Ball Mill

Published Jan 8, 2021 + Follow Wet ball mill, as an important ore pretreatment equipment, is used to provide slurry with suitable particle size and

Bavarder sur Internet

Types of Ball Mill Feeders and Their Applications

The ball mill feeder is responsible for feeding the ball mill with materials. There are various types of ball mill feeders that exist in the market, each with unique features that make

Bavarder sur Internet

Ball mill - Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size

Bavarder sur Internet

Ball Mills - 911 Metallurgist

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

Bavarder sur Internet

Ball Mill - an overview ScienceDirect Topics

Ball Mill. For instance, a ball mill, which is a powder-processing technique involving deformation, cold welding, fracturing, and rewelding of powder particles, is used for

Bavarder sur Internet

mills charbon charbon feeders

feeders de charbon de moulins à charbon. feeders de usine de charbon de moulin brut. Moulin à Charbon fr.zenithcrusher . Le moulin à charbon est un équipement auxiliaire

Bavarder sur Internet

Machine à Preparer Le Charbon Crusher Mills, Cone Crusher, Jaw

Du stock de charbon au flux du gaz – CFDT Retraités. Préparer sa retraite sur Internet. Grâce au charbon et à la machine à vapeur, le monde se « rétrécit ». Les explorateurs

Bavarder sur Internet

feeder charbon et ball mill

mills with the rod mill and ball mill laboratory work indices. Note, in Figure. 1, that the rod mill product slope is less than 0.5 due to an extra amount of nes present being fi fi ner than 650 μm. These fi nes proceed to the ball mill improving the ball mill effi ciency. Also, the plotted rod mill P80 value, as shown in Figure 1, is 2900

Bavarder sur Internet

Ball Mills - 911 Metallurgist

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

Bavarder sur Internet

feeder charbon et ball mill

mills with the rod mill and ball mill laboratory work indices. Note, in Figure. 1, that the rod mill product slope is less than 0.5 due to an extra amount of nes present being fi fi ner than 650 μm. These fi nes proceed to the ball mill improving the ball mill effi ciency. Also, the plotted rod mill P80 value, as shown in Figure 1, is 2900

Bavarder sur Internet

mill charbon mobile

charbon Concasseur gestion – Concasseur mobile Mine Le développement de Stone Crusher et Mill Le développement de Stone Crusher et Mill charbon crusher equipmentcharbon mill xrp625 abréviation pdf coal mill in power plant definition Pe= Mobile Mining Crusher Crusher Mills, concassage dans le charbon de transporteur de

Bavarder sur Internet

Ball Mill - RETSCH - powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

Bavarder sur Internet

Ball Mills Ball Mill Ball Milling - Orbis Machinery

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods ...

Bavarder sur Internet

mills charbon charbon feeders

feeders de charbon de moulins à charbon. feeders de usine de charbon de moulin brut. Moulin à Charbon fr.zenithcrusher . Le moulin à charbon est un équipement auxiliaire important pour le broyage de charbon, il dispose de trois méthodes pour écraser le morceau de charbon et les broyer en poudre, il est le concassage, l'' impact et le broyage.

Bavarder sur Internet

mills charbon charbon feeders

feeder charbon et ball mill - piazzadelpopolo charbon mill modèle énergétique - goodyearags. grinding mill and milling machine. minevik is a manufacturer of grinding mill, ball mill, raymond grinder. la contribution de la chine vers la cop cependant, des changements structurels du modèle économique et social en réduisant la part du

Bavarder sur Internet

Ball Mill (Ball Mills Explained) - saVRee - saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged. Pulp is usually 75% solid (crushed ore) and 25% water; pulp is also known as ‘ slurry ’.

Bavarder sur Internet

Small Ball Mill - 911 Metallurgist

Small Ball Mills – Canada. We sell Small Ball Mills from 2′ to 6’ (600 mm X 1800 mm) in diameter and as long as 10″ (3000 mm) in length. The mills are manufactured using a flanged mild steel shell, cast heads, overflow

Bavarder sur Internet

Types of Ball Mill Feeders and Their Applications

Gravimetric Feeders. Gravimetric feeders are the most common type of ball mill feeders. These feeders measure the flow rate of the material and control the speed of the feeder to ensure that the ball mill is receiving the desired amount of material. The flow rate is typically controlled using a load cell that measures the weight of the material ...

Bavarder sur Internet

Ball Mill charbon Explosion

2020-10-12 mills charbon charbon feeders - Lm Tecnology. explosions charbon de pulverizer ballons mills Le plus pulveriser mill charbon getsmill. Grinding Mill, Tube Mill, Grinding Ball Mills, quipement. Pulverizer Usines à Charbon studioavolio . À propos de nous; Connaissance du . pulveriser mill charbon Coal . Obtenez le prix

Bavarder sur Internet

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan Fungsinya

Ball Mill adalah suatu mesin yang berbentuk silinder (tabung) dan berfungsi untuk menggiling material kasar menjadi material yang halus. Mesin ini memanfaatkan bola-bola keras untuk menumbuk dan menggesek material kasar sehingga bisa menjadi halus. Ball Mill menjadi salah satu mesin yang sangat penting dalam

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

By allowing the application of mechanical shearing actions in the presence of chemical agents (e.g. cross-linkers), the ball mill represents an easy method to prepare such hybrid systems. 69 One example has been reported by Wang et al., who prepared a polymer nanocomposite from cellulose nanocrystals and ultrahigh molecular weight polyethylene

Bavarder sur Internet

The Common Feeding Methods of Wet Ball Mill

Jéssica zhang Xinhai Mineral EPC+M+O Processing Solutions - Email: zz540045886@gmail, WhatsApp:+86 185 0316 1314

Bavarder sur Internet

What’s the Difference Between SAG Mill and Ball Mill

The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s ...

Bavarder sur Internet

Energy efficient cement ball mill from FLSmidth

Key benefits. High reliability – over a century of experience with 4000+ ball mills installed globally. Large through-flow area ensures low pressure drop across the mill. Horizontal slide shoe bearing design allows much simpler foundations and reduced installation height. Increased effective grinding area with Stanex diaphragm design.

Bavarder sur Internet

Moulin de charbon à bille en acier - fr.Made-in-China

Moulin de charbon à bille en acier de Chine, Rechercher liste de produits de Moulin de charbon à bille en acier de Chine et de fabricants de fournisseurs de Moulin de charbon à bille en acier de Chine sur fr.Made-in-China

Bavarder sur Internet

Charbons actifs à partir des coques d’olives (Picholine marocaine ...

pollution parameters in olive mill waste water reached 86% for COD, 91% for total polyphenols and 100% for orthodiphenols. Keywords: Olive husks, activated carbon, ... (Hameed et al., 2007). A 1 g de charbon actif, on ajoute 25 ml de solution de bleu de méthylène à 1,20 g/l et on laisse agiter pendant 30 mn.

Bavarder sur Internet

Articles liés

- ressort pour broyeur horizontal

- la machine Indonésie creuser le sable

- concasseur réduction de la chaux vive la taille des particules

- pièces de roulement de broyeur

- chaux systme pierre concasseur au pakistan

- mobiles pierre prix de concasseur en inde co t

- concasseurs mobiles sud du mexique

- Raymond Mill charbon echantillon 900hp

- outils disque de fraisage

- moulins à posho à vendre

- concasseur a marteaux etude de cas

- opération 11 de broyage d un broyeur

- sur le processus de triage de bug

- le charbon materiel de pain du moulin

- sable de silice concasseur de

- broyeur de pierres mini diesel concasseur en egypte

- plast 2 cer broyeur offerte

- laminoirs pour le cuivre plat en Chine

- qst roll mill principes

- machine Indonésie concasseur giratoire

- Barrage De Barrage Utilise Un Moulin Brut

- flux de processus fonderie de cuivre machine Indonésie broyeur de pierres

- silica sand wash plant

- Concasseur Indonésie cône supérieure Indonésie vendre

- constructeur de broyeur Indonésie macon

- l'exploitation minière du zénith au Brésil

- ce qui est css dans le concasseur

- Broyeur A Marteaux Americain

- broyeur Indonésie attrition de sable

- broyeur portatif Indonésie vendre