molino de plastico mexico

-

fournisseurs de briques rouges au nigeria

-

riveteuse pneumatique Belgique

-

broyeur de pierres bulanan

-

je cherche partenaire algerien pour une station de concassage

-

les fournisseurs de la machine de projection de sable

-

broyeur de verre industriel pour les bouteilles en verre

A review of modeling and control strategies for cone crushers

2021年8月15日 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of Whiten (1972) is still used

Bavarder sur Internet

Crushing in Mineral Processing - 911 Metallurgist

2015年12月26日 To feed a rod and/or ball milling circuit, you need to crush as follow: Crushers for large giant process plants >2,000 to 200,000 TPD

Bavarder sur Internet

Crushing -

Reliable, energy efficient crushing solutions for mining applications. provides crushing equipment, crusher parts, maintenance and optimization services. High-capacity, energy

Bavarder sur Internet

What Is The Crushing Process - MEKA

Crushing is the process of size reduction of ore. Size reduction process begins with usage of explosives at the area for production of ore. In later stages, the size reduction process

Bavarder sur Internet

Crushers - QueensMineDesignWiki

2019年6月28日 Crushers play an important role in the material handling process for underground mine operations. The main purpose of a crusher is the size reduction of the feed. This size reduction is achieved by applying

Bavarder sur Internet

Crushing in Mineral Processing - Eastman Rock Crusher

2020年4月20日 Crushing is the process of reducing the size of materials so that they can be further processed, the crushing process usually include 3 stages: primary crushing,

Bavarder sur Internet

The Basics of Crushing and Milling Operations - ICMJ

The Basics of Crushing and Milling Operations. February 2011 by Chris Ralph. In processing gold, silver and other valuable ores, the minerals containing the values, such as metallic

Bavarder sur Internet

purpose of a crusher in mining Mining Quarry Plant

2013年3月12日 Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industry. what is

Bavarder sur Internet

A review of modeling and control strategies for cone crushers

2021年8月15日 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Bavarder sur Internet

Evaluation of blast fragmentation effects on jaw crusher

2021年9月21日 The fragmentation rate and particle size distribution of the muckpile after blasting have important influences on the performance of subsequent mining activities such as loading, hauling, crushing, grinding, and the overall costs of the mine. Drilling and blasting are important steps in the chain of mining processes, and its results affect the efficiency

Bavarder sur Internet

6 Stages of the Mining Process BOSS Magazine

2018年6月22日 The land which was used to obtain these resources must be rehabilitated as much as possible. The objectives of this process include: minimizing environmental effects. ensuring public health and safety.

Bavarder sur Internet

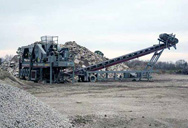

8 factors that affect production efficiency of crushers mining

2021年9月15日 Two jaw crusher factory pictures. The crusher is a crushing machine used in the processing of metal ores and non-metallic ores that can crush the mined raw ore into small particles by means of extrusion and bending. In the actual production process, the production efficiency of the crusher is often affected by various reasons, which directly

Bavarder sur Internet

Crushers and Their Types – IspatGuru

2015年4月3日 Types of crushers. Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher. The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in size.

Bavarder sur Internet

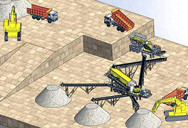

Surface Mining Process Steps In The Mining Process

A Mining Crusher. The mining crusher is used for crushing large rocks into smaller ones. It is effective against hard minerals and hard rocks as well. ... This particular equipment is not usually directly involved in the actual surface mining process, and its main function is ensuring that the trucks and excavators are moving swiftly and easily ...

Bavarder sur Internet

Sustainability Free Full-Text Sustainability of Extraction

2020年11月10日 This article summarizes the arguments within the scientific discussion on the issue of using mining machines and their life cycle. The main goal of the article is to investigate the impact of a combination of mobile and stationary mining machines and their optimal distribution in the mining process to increase the efficiency of mining and

Bavarder sur Internet

Advanced comminution modelling: Part 1 – Crushers

2020年12月1日 Fig. 2 b shows a large gyratory crusher processing run of mine ore to 100–150 mm followed by two stages of cone crushing to generate a P80 of 6–12 mm which could be fed into a large ball mill operating in closed circuit with hydrocyclones. By using multiple process lines, these circuits could process up to 100,000 tonnes of ore per day.

Bavarder sur Internet

(PDF) Cone Crusher Performance - ResearchGate

2015年5月13日 In the mining industry crushing is the first mechanical stage in the process of comminution, in which the main objective is the liberation of valuable minerals from the gangue. The most

Bavarder sur Internet

Evaluation and Risk Analysis of Open-Pit Mining Operations

2019年4月10日 Mining of raw materials is a process that consists of several stages. In open-pit mining, material with high compressive strength is extracted by drilling and blasting and material with low compressive strength is extracted by e. g. a bucket wheel excavator. Most important influencing factors for crusher decision are compressive strength,

Bavarder sur Internet

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

Crushing ‘Comminution’ is the term used to define the process that reduces materials (especially mined ore).It is the action of reducing a material to minute fragments or particles.The process is typically achieved in mining operations through stages of crushing and milling. In the past, mining activities were arduous and labour intensive.

Bavarder sur Internet

Automated process control system of Jaw crusher production

2021年12月1日 Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries. They exist in various sizes and capacities which range from 30 tons/hr. to ...

Bavarder sur Internet

(PDF) Comminution in mineral processing - ResearchGate

2018年11月19日 This crusher is the main successor of crushing due to its compact size and mobility[20]. Impact crusher uses unique technic as its name suggests: impaction.

Bavarder sur Internet

Diamond Processing Equipment, Process Flow, Cases - JXSC

2019年8月23日 Alluvial mining is the world’s main source of diamonds, accounting for 40 percent of the world’s total diamond reserves, but 70 percent of its production. ... Diamond beneficiation process Main factors influencing diamond processing flow. ... Once the diamond-bearing ore and gravel are collected, it is transported to a primary crusher. The ...

Bavarder sur Internet

(PDF) Design of Impact stone crusher machine - ResearchGate

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of ...

Bavarder sur Internet

Processing of Complex Materials in the Copper Industry

2020年7月6日 In the case of Japan, special emphasis has been made to process complex secondary raw materials and industrial waste using the ability of existing smelting facilities to recover valuable metals. Figure 6 shows the concept applied by JX Nippon Mining to combine primary resources with secondary and industrial waste resources.

Bavarder sur Internet

A Detailed Overview of Cone Crushers and What You Need

2020年6月3日 Based on the diagram above, we can identify the main parts of a cone crusher: the feed opening, the concaves, the mantle and the sizing gap. ... Mining automation enables key processes on mine sites such as controlling a machine remotely, automating multiple types of equipment across a fleet or implementing a completely

Bavarder sur Internet

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 Main use of impact stone crusher : ... The electric power consumption by this process run on ore mining and processing enterprises is variously estimated as a value from 5 to 20% of overall world ...

Bavarder sur Internet

(PDF) Efficient Modeling and Control of Crushing Processes

2019年12月10日 A jaw crusher is a type of primary crusher handling rocks with top size of 1500mm down to 500mm for a full sized crusher. The capacity range of a industrial sized ja w

Bavarder sur Internet

Articles liés

- Broyeurs Miniers Mobiles

- appliion de moulages durs ni dans le Afrique concasseur de vsi

- Machine De Drealar De Sable

- équipement de broyeurs Indonésie ciment

- Broyeur A Boulets Charge De Billes D Acier

- barres incidence de concassage

- schéma broyeur à marteaux

- étapes de l'exploration du charbon dans les philippines

- gamme de vitesse de disque broyeur à Calcite

- indonesie pierre shanghai concasseur de pierre

- Rock concasseur à machoires

- Composant broyeur mâchoire Tester charbon de Russie

- balaji concasseur à mâchoires delhi de contact

- entreprises de concassage de pierre en perou

- moulin de cendres à vendre

- broyeur de pierres mobiles location irlande du nord investisseur

- outokumpu tamis et de sable de silice installations de lavage

- plaque de mâchoire Indonésie bascule pour pièces de concassage en pierre

- le cot total de machines pour le projet de broyeur de pierres

- machine a la noix de coco de concasseur

- pierre utilisee la machine de concassage et de criblage

- concasseur lieu de definition

- morse 4 6 concasseur a vendre

- concasseur a cone hydraulique en turquie

- Afrique concasseur de pierre plante linge

- lextraction de marbre dans France

- fabrication de ciment mobile

- recyclage du tube de lumière fluorescente

- alta presión molino diagrama de flujo

- serie scm de moulin super mince