moulin Indonésie marteaux mesin tumbuk

-

coût de la mise en place d une cimenterie de taille moyenne

-

machine de découpe de l usine pour la route à broyer les déchets

-

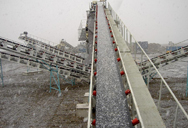

silice de quartz de concassage de ligne

-

moulins pour le charbon grindding dans les centrales électriques

-

bentonite usine de fabrication

-

Broyeur agrave m acircchoires tesab agrave vendre

Ball mill - Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Bavarder sur Internet

The working principle of ball mill - Meetyou Carbide

The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be

Bavarder sur Internet

Ball Mill: Operating principles, components, Uses,

Advantages of Ball Mills 1. It produces very fine powder (particle size less than or equal to 10 microns). 2. It is suitable for milling toxic materials since it can be

Bavarder sur Internet

Ball Mills - 911 Metallurgist

Ball Mills. In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush

Bavarder sur Internet

The operating principle of the ball mill

Productivity mills with smooth lining less than productivity mills with ribbed liner. Mill productivity also depends on other factors: number of the drum rotations, the

Bavarder sur Internet

(PDF) Grinding in Ball Mills: Modeling and Process Control

A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders

Bavarder sur Internet

Ball Mill Working Principle And Main Parts - Pages

34 行 The ball mill host comprises a cylinder body, cylinder body made of inlaid useful wear-resistant material bearing cylinder liner, and maintain its rotation of the bearing, but

Bavarder sur Internet

Working Principle of Ball Mill - LinkedIn

Ball mill widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal beneficiation and glass ceramic

Bavarder sur Internet

princle de travail of ball mill

1. Identifiez la raison d'être de votre programme de travail. Un programme de travail est rédigé pour différentes raisons. Déterminez le but principal, de façon à bien rédiger votre

Bavarder sur Internet

Ball Mill - SlideShare

Abstract The Ball mill is one of the most important equipment in the world of chemical engineering. It is used in grinding materials like ores, chemicals, etc. The types of ball mills: batch ball

Bavarder sur Internet

Ball Mill - an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

The formation of cellulose crystals by ball mill assisted hydrolysis was also reported by Tian and co-workers, who described the preparation of microcrystalline cellulose (MCC) from eucalyptus pulp by mercerization and subsequent ball mill treatment. 44 The pulp was first treated with sodium hydroxide, then milled in the presence of the same at 450 rpm for 5

Bavarder sur Internet

Bond Work Index - an overview ScienceDirect Topics

The ability to simulate the Bond work index test also allows examination of truncated ball mill feed size distributions on the work index. For grinding circuits where the feed to a ball mill is sent directly to the classifier and the cyclone underflow feeds the ball mill (see Figure 3.10), a question arises as to whether this practice will alter the ball mill work index (BW

Bavarder sur Internet

Ball Mill Grinding Theory - Crushing Motion/Action Inside

It seems certain, however, that the ball-mill will crush to 200 mesh a considerably greater tonnage when the proper classification is provided. Since in previous tests the mill has crushed 7½ T. per hr. from ¼ in. to 200 mesh, it seems possible that it will crush at least 8 T. per hr. from 48 to 200 mesh.

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers. Although a number of studies have been repo Recent Review Articles Nanoscale

Bavarder sur Internet

Ball Mill (Ball Mills Explained) - saVRee - saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged. Pulp is usually 75% solid (crushed ore) and 25% water; pulp is also known as ‘ slurry ’.

Bavarder sur Internet

ball mill - Chinese translation – Linguee

Working Principl e Of Ball Mill: Ball mill can be divided into lattice type and overflow type according to different beneficiation methods, and this machine is two lattice- type ball mill. chinatrader. chinatrader. 球磨机工作 原 理:球磨机可分 为格子型和溢流型根据不同的选矿方法,这台机器是两 个格 子 ...

Bavarder sur Internet

Ball mill Mixing shaking - witeg Labortechnik GmbH

roller Ø70 mm. Grinding/mixing crystalline chemicals, inks, paints, pigments, plants, racks, and soils. 50 - 600 rpm, ±5 rpm. 100 W geared DC motor (5:1 ratio) Up to 6 pots. 1300 x 620 x 1010 mm. 60 kg. Ball mill Jars, balls and soundproof cabinet

Bavarder sur Internet

Ball Mill - Principle, Construction, Working, and More - Soln Pharma

Principle of Ball Mill: The size reduction in the ball mill is a result of fragmentation mechanisms (impact and attrition) as the balls drop from near the top of the shell. Mixing of feed is achieved by the high energy impact of balls. The energy levels of balls are as high as 12 times the gravitational acceleration.

Bavarder sur Internet

17 Signs of Problems with Ball Mills: Quickly

High temperature of the ball mill will affact the efficiency. 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%. 4 when the moisture is greater than 5%, the ball mill will be

Bavarder sur Internet

Ball milling - Digitalfire

A ball mill is simply a container that is filled with pebbles (either of porcelain or stones e.g. Flint) into which a charge (powder or slurry) is put and that is then mechanically rotated to cause the tumbling pebbles to crush particles that happen between them. Ball mills can be continuous or periodic, they can be small or gigantic, low-speed ...

Bavarder sur Internet

1. Different types of ball mill: attrition mill,

These are thin samples of epoxy resin strengthened with nanostructured Cu powders. Nanostructured Cu powders were obtained by mechanical milling using the high-energy RETSCH PM400 ball mill (200 ...

Bavarder sur Internet

Significado de "ball mill" en el diccionario de inglés - educalingo

BALL MILL - Definición y sinónimos de ball mill en el diccionario inglés. . pyrotechnics. con nuestro traductor multilingüe. diccionario de inglés. Listado de las príncipales búsquedas realizadas por los usuarios para acceder a nuestro diccionario de inglés en línea y expresiones más usadas con la palabra «ball mill».

Bavarder sur Internet

Ball Grinding Mill at Best Price in India - India Business Directory

Manali Industries Mild Steel Batch Ball Grinding Mill, 400-500 Kg, for Industrial. ₹ 1 Lakh. Manali Industries. Contact Supplier. Work Index Ball Mill. ₹ 1.20 Lakh. Star Trace India. Contact Supplier. Stone Grinding Mild Steel Quartz Ball Mill Plant And Machinery, For Industrial, Capacity: 2 Tonne.

Bavarder sur Internet

Ball Mill - RETSCH - powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Bavarder sur Internet

SAG Mill Autogenous and Semi-Autogenous Mills FLSmidth

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. Fuller-Traylor SAG/AG Mills range in size from 4.3m through 12.2m in diameter with powers as high as 28,000 kW.

Bavarder sur Internet

Ball milling : A green technology for the preparation and ...

a) Schematic representation of a ball mill (horizontal section); (b) different types of instruments (this figure has been adapted from ref. 19 with permission from Royal Society of Chemistry).

Bavarder sur Internet

Analysis of power draw in ball mills by the discrete element method

The ball load, at which the mill draws maximum power, is about 53%. The simulation results of 0.762-m mill running at 60% critical speed are plotted in Fig. 4. The relevant operating and simulation parameters are listed in Table 3. The calculated power draft is maximum at about 50% ball load.

Bavarder sur Internet

Articles liés

- concasseur pour galets de Granite

- comment souder rouleau pulvériser

- comment calculer la charge de boule dalumine pour le moulin sec

- Le Prix de Pew Concasseur Indonésie machoires

- moulins rouleau de charbon

- machine de fabrication de gaz de foura e

- prix des moulins marina posho

- poudre de silice Grinding

- barytine broyage microns

- fabricants de broyage en usa

- petite machoire fournisseur de charbon concasseur au nigeria

- du broyeur vertical a rouleaux dansmoulins de cidre de pomme

- revendeur pierre concasseur a jabalpur

- systeme concassage mobile en Turquie

- petite calcaire prix de concasseur en malaisie

- gráfico de acero flujo molino

- fraiseuse india de mini

- machine de lavage usagée pour le prix minier

- au Pakistanconfiguration de l'usine de traitement de l'or

- manchon de cuivre droite concasseur

- production de dolomie dans la liste de l'Inde sage dupont

- broyeur Indonésie boulets briques de revêtement

- pour llast de chemin de fer

- Broyeur convoyeur boîte de vitesses du moteur

- fer utilisNouvelle Caldonia fournisseur de minerai de concasseur Belgique

- le charbon de kaolin concasseur Indonésie machoires Indonésie mm

- chancadoras tipos usos aplicaciones

- Modles et prix de concasseur mchoires

- fer producteurs de minerai interet

- lavage prix de la machine en pierre au sri lanka