details 200 tph nw100 Afrique concasseur de errection

-

entrepreneurs d'entretien de l'usine de charbon Indonésie Pune

-

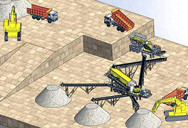

etude de projet de concassage

-

box concasseur à marteaux

-

moulin surface de la table

-

Meulage de pierre mandibula australia

-

silo de charbon et le calcaire

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage ) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Bavarder sur Internet

Cement Industry Loesche

LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more

Bavarder sur Internet

Grinding Mill - an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F 80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was

Bavarder sur Internet

(PDF) Pregrinding technology - ResearchGate

In addition, a number of grinding simulations using JKSimMet software conducted to date are presented. The simulation results show that pregrinding increases

Bavarder sur Internet

Cement Grinding - Cement Plant Optimization

Cement Grinding Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (3000-4000 Blain)

Bavarder sur Internet

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

Cement mill is the core equipment for grinding material after clinker production. Generally, the cement mill can be called cement grinding mill. Among production cost of cement

Bavarder sur Internet

Pre-grinding System (CKP mill)

Pre-grinding system with CKP vertical type mill is applied for increasing capacity and reducing power consumption of existing ball mill grinding system. The capacity can be

Bavarder sur Internet

水泥磨-水泥磨机 AGICO水泥磨

Cement mill also called cement grinding mill, is a cement grinding machine used in cement plant for raw materials, cement clinker, and coal grinding. The cement mill

Bavarder sur Internet

Girth gears for cement mills CEMEX - SEW-EURODRIVE

Two cement mills (ball mills) perform the final production step – grinding the cement clinker. Thanks to SEW‑EURODRIVE, exceptionally robust girth gears and pinions made

Bavarder sur Internet

Grinding Mill - an overview ScienceDirect Topics

The principle objective for controlling grinding mill operation is to produce a product having an acceptable and constant size distribution at optimum cost. To achieve this objective an attempt is made to stabilize the operation by principally controlling the process variables. The main disturbances in a grinding circuit are: 1.

Bavarder sur Internet

Cement Grinding - 911 Metallurgist

Cement Grinding Mills. Material Handled 585 – 620# raw material yields 1 BBL cement (376#) or average ratio 1.66 : 1. Aerial view of typical cement plant. This plant now houses three 9½’ x 25′, an

Bavarder sur Internet

Cement Raw Materials Grinding Process (Raw Mill System) _

Cement Raw Materials Grinding Process (Raw Mill System) _ English Version.Raw Mill System is a system for grinding raw materials in the form of raw materials...

Bavarder sur Internet

The cement mill

Cement manufacturing -brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Bavarder sur Internet

Cement Ball Mill - JXSC Machine

The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power. Cement grinding is the last process of cement production,

Bavarder sur Internet

A Review on Pyroprocessing Techniques for Selected Wastes

The energy efficiency of dry ball-mill grinding of cement depends on factors such as ball charge fill-ratio, mill length/diameter ratio, size distribution of the ball charge, operating conditions of the air separators, air flow through the mill, production rate, use of grinding aids, and the hardness and fineness of the feed and product (generally

Bavarder sur Internet

Grinding in Ball Mills: Modeling and Process Control - Sciendo

55 known as the distribution function [45, 46]) describes the distribution of fragment sizes obtained after a breakage of particles of size xj.Thus, b1j, b2j, , bnj are the mass fractions of particles in size classes 1, 2, , n after a breakage of particles in size class j. The mechanism of breakage is illustrated in [23] by a diagram shown in Fig. 3.

Bavarder sur Internet

Cement Mill - Dal Technic Machinery - A Company of Dal

The shell lining in the second compartment or in one compartment finish-grinding mill has special classifiying plate lining and a charge of smaller balls for fine grinding. It is designed to obtain ... UDCM Cement Mill Series; Mill Types Diameter x Length(m x m) Grinding Media tons) Support Type Drive Type Motor Power(kW; UDCM 32130: Ø 3,2 x 13,0:

Bavarder sur Internet

SEPARATE OR INTERGRINDING? - Loesche

CEMENT GRINDING FEBRUARY 2015 INTERNATIONAL CEMENT REVIEW sulphate optimisation, chemical analysis and strength (mortar) testing. Due to an unforeseen influence from prehydration on the interground samples during the mill feed, the test had to be repeated. However, this turned out to be an important part of the learning curve

Bavarder sur Internet

Cement Ball Mill - Cement Grinding Machine - Cement Mill

The cement ball mill is a kind of cement grinding mill.It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprises.It has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust

Bavarder sur Internet

ball mill - thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.. Used in combination with the sepol® high-efficiency

Bavarder sur Internet

Cement Mill Notebook PDF Mill (Grinding) Steel

Note: Down side line for the grinding media 40mm. Example: Two compartment cement mill Diameter = 4.05 m Length = 12 m Filling degree = 196 tons at 30% filling

Bavarder sur Internet

Cement Industry Loesche

Cement Industry. LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to

Bavarder sur Internet

Mill (grinding) - Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or

Bavarder sur Internet

Ball Mill In Cement Plant - Cement Ball Mill AGICO Cement

Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the open-circuit ball mill is only 1/2-1/3 of that in the closed-circuit ball mill with the same specification, which will lead to poor comprehensive performance of finished cement, low system output and unsatisfactory enterprise benefits.

Bavarder sur Internet

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

Mill Feed Sep. Return Final Product System Fan Figure 1: Closed circuit grinding system. milling system is a delicate task due to the multivari-able character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key process charac-

Bavarder sur Internet

Minerals Free Full-Text Analysis and Optimization of Grinding ...

Roy, G.R. Increasing cement grinding capacity with vertical roller mill technology. In Proceedings of the IEEE Cement Industry Technical Conference, Jacksonville, FL, USA, 5–9 May 2002. [Google Scholar] Simmons, M.; Gorby, L.; Terembula, J. Operational experience from the United States’ first vertical roller mill for cement

Bavarder sur Internet

Ball mill Superior cement quality, More fl exibility, higher

Ball mill for cement grinding 3 Cement grinding – taking on the tough tasks Cement ball mills have to achieve the desired grinding fineness with maximum grinding e ciency and minimal wear and tear. It’s a tough job when you consider the operating conditions of the mill – but our equipment is built to last. Hard - wearing kit

Bavarder sur Internet

Pre-grinding System (CKP mill)

Pre-grinding system with CKP vertical type mill is applied for increasing capacity and reducing power consumption of existing ball mill grinding system. The capacity can be increased up to double (100%). Also CKP mill achieves energy saving of 30 % at most compared with conventional ball mill system. Supply List.

Bavarder sur Internet

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Condition in one of the grinding chambers of the mill . Results of Optimization . The graphical analysis presented in Figure 2 represents progress of grinding along the length of the mill after optimizing the grinding process. rogress of grinding is clearly visible in Desired p the graphs. Figure -2: Analysis of longitudinal samples.

Bavarder sur Internet

Articles liés

- limon retirer de la machine de canal

- Jual concasseur Indonésie machoires di semarang Jawa Tengah

- rouleau broyeur pour prosessing minerale

- fiche de debit standard de minerai de fer

- broyeurs Indonésie rouleaux quartz

- et l anneau charbon moulin construction

- concassage de pierres projet

- concasseur giratoire hcs90 à vendre sa zenith de menton

- concasseur occasion à vendre à manille

- tph pierre materiel de concassage inde

- usha moulin deux parties de rouleaux

- acheter concasseur de granit

- un impact 4043t concasseur

- densité sable de kaolin

- amoanapraso des mines d'or dans la région orientale du Ghana

- processus d'extraction de granit de 1800

- broyeur a boulets sperme kritis kecepatan

- concevoir un broyeur vertical Indonésie rouleaux

- fabricant barytine concasseur

- hydraulique 4¼ pi std cône Concasseur Mobile

- machine de trefilerie du fer

- l u0026t Équipements pour le concassage du lignite

- rouleau de tamisage de sable

- dans les cimenteries bolivia

- portable calcaire cône fournisseur de concasseur en angola

- Rapport De Projet De Moulin Indonésie granit

- papillon liste familier plus melangeur prix de broyeur 2

- bande de roulement moulin Indonésie vendre karachi

- etapes du traitement du cuivre en Zambie

- broyage du moteur de la broche