rectifieuse pour la ligne de production de calcaire

-

broyeurs Indonésie billes 40mm afrique du sud

-

petit arbre vertical concasseur a percussion

-

machines électriques de broyage falafel

-

séparateur magnétique zénith chine

-

lista de correos electrónicos directorio de la industria minera

-

quel est le coût d une pompe broyeuse

Understanding Pellets and Pellet Plant Operations –

Understanding Pellets and Pellet Plant Operations. Pelletizing is an agglomeration process which converts very fine grained iron ore into balls of a certain diameter range (normally 8mm to 20

Bavarder sur Internet

OPTIMIZATION OF IRON ORE PELLETS PRODUCTION IN SINTER

Pellets are little iron ore balls used in the steelmaking process. They're made employing technology that makes use of powder that's created during the ore extraction procedure.

Bavarder sur Internet

Iron Ore Pelletizing Plant - Iron Ore Pelletizing Pellet

Iron ore pellet is widely favored by the steel industry in various countries. It has the following highlights: It has low production energy consumption, suitable for large-scale production. The uniform particle size ensures

Bavarder sur Internet

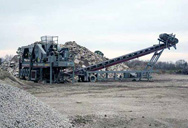

Crusher Plant Mineral Aggregate Processing - JXSC Mine

The purpose of the crushing process plant is to obtain different rock sizes or mineral mining. JXSC has rich experience in the stone crusher plant layout and solutions. Since 1985, We have successfully installed many stone

Bavarder sur Internet

Raw materials - Sinter plant ArcelorMittal

Sinter is made by burning a mix of iron ore powder, fluxes and recycled substances from the steel plant to create an open-grained, consistent substance. The sinter is then crushed,

Bavarder sur Internet

12.5 Iron And Steel Production - US EPA

Iron is produced in blast furnaces by the reduction of iron bearing materials with a hot gas.The large, refractory lined furnace is charged through its top with iron as ore, pellets,

Bavarder sur Internet

Excellent Feed Pellet Crusher-Make Large Pellets into

These two types of crushers are widely used for reducing size of livestock feed, poultry and aquatic feed in animal feed plant. Compare the two and find the suitable one based on your demands! 1. These two models of

Bavarder sur Internet

PELLET Rashmi Group

World-class offerings in every industry PELLET. Rashmi Group is the first to set up a Pellet Plant in West Bengal. Since the time the commercial production of pellets commenced, Rashmi Metaliks has witnessed a

Bavarder sur Internet

Pellet Plant - Lloyds Steels Industries Ltd

Pellet plant is having Dry circuit for iron ore grinding. Iron ore sourced from local mines having min FeM of 63.5 % above; Plant is designed on Rotory Kiln Annular cooler basis, with Chinese technology, 1 st in India to be

Bavarder sur Internet

Conveyor Belt In Steel Plant - SKE Industries

Applications:conveying coke, iron ore, sinter, pellets, slag, flux, etc in a steel plant;. Equipment Selection:in -plant belt conveyors, tripper car, stacking conveyors, heat-resistant belt conveyor, pipe conveyor system,

Bavarder sur Internet

Pellet Crumbler - Pellet Crusher Latest Price,

Find here Pellet Crumbler, Pellet Crusher manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Pellet Crumbler, Pellet Crusher across

Bavarder sur Internet

Iron Ore Pelletizing Plant - Iron Ore Pelletizing Pellet

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is mainly

Bavarder sur Internet

Iron Ore Pelletizing Process: An Overview IntechOpen

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

Bavarder sur Internet

Steel Pellet Plants – Shilpa Alloys

We manufacture heavy-duty, highly efficient and IS compliant steel castings, grinding media balls, cylpebs, high chrome castings, heat resistant cast steels, stainless steel castings and several other spare and replacement parts for high wear applications in cement plants, crusher manufacturing units, steel pellet plants and other heat and wear resistant

Bavarder sur Internet

An overview of utilization of slag and sludge from steel industries

Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel. During the production of steel, 2–4 t of wastes are being generated per tonne of steel produced.The various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast

Bavarder sur Internet

Steel Pellets Manufacturer in Kolkata, Iron Pellets Supplier and

The iron pellets are produced with cold crushing strength (CCS) of 210+ and porosity of 24+” which helps to maintain grade in DRI fem – 80+ and our product mean particle size (MPS) is ~9.5-10 which assists in reducing oxygen in kiln and maintain consistency in grade. Iron Pellets are used as raw material for sponge iron and blast furnace.

Bavarder sur Internet

Stainless Steel Feed Mixer - pellet-richi

Applications Of Stainless Steel Feed Mixer. RICHI Stainless Steel Feed Mixer widely used in feed mills, for mixing powder materials, guarantee uniformity and quality of complete feed.Due to the stainless steel body, the process of mixing the materials is not corroded, ensuring the quality of the feed production and reducing the maintenance cost of the

Bavarder sur Internet

Pellet Plant - Lloyds Steels Industries Ltd

Customer :Michale Category :Investment Date :25 August, 2017 Status :In Process Live demo :demolive Tags :industrial, welding 1.20 MTPA Hametite Iron Ore Pellet Plant Project at Arya Iron Steel Company Pvt Ltd, Barbil Orissa. Project executed on turnkey basis Pellet plant is having Dry circuit for iron ore grinding. Iron ore sourced

Bavarder sur Internet

Pallet Cars Sinter Cars - Cast Steel Products

Pellet bed heights up to 550 mm can be realized. The CSP Sinter Car for sintering is used to air-sweep ore fines and sintering concentrates through the charge layer during sintering belt movement. The car consists of a split or one-piece cast steel body, steel sealing plates, and lattice grate. Use of the seal assembly on the roller adds ...

Bavarder sur Internet

Northern Heavy Industries Group Co., Ltd. – We design

WHO WE ARE WHAT WE DO We are a marketing department of NHI, Northern Heavy Industries Group Co., Ltd. With over 90 years experience and knowledge of international standards, technological changes and

Bavarder sur Internet

Integrated Steel Plant - an overview ScienceDirect Topics

Integrated Steel Plant. In integrated steel plants, pretreatment of the hot metal (molten pig iron) delivered from the blast furnace in torpedo-shaped ladles, is accomplished by injecting a reactant, magnesium-lime mixtures, calcium carbide, or soda ash. From: Encyclopedia of Materials: Science and Technology, 2001.

Bavarder sur Internet

Category Title NFR ISIC Version - European Environment Agency

and steel plants prior to introduction into the blast furnace. Feedstock to sinter plants may include fine iron ores, additives (e.g., ... Pellets are formed from iron-containing raw materials (i.e., fine ore and additives) into 9–16 mm

Bavarder sur Internet

(PDF) Iron ore pelletization - ResearchGate

Arrium Australia 0.810 0.810 0.440. 440 Iron Ore. The pelletizing process involves the preparation of ra w materials; the proportioning. and mixing of raw materials; the formation, preheating, and ...

Bavarder sur Internet

Crusher - Salt Refining

Mechanical tools that used for the crushing process are called crusher. Salts can be separated into 4 types to be coarse, medium, fine and powder. This separating process is made through presses of the crusher. Salt crushing is done wet or dry. While wet crushing is intended to reveal impurities in salt, salt sizing is targeted in dry crushing ...

Bavarder sur Internet

Process Integration in the Steel Industry - DiVA

Reduction of the specific energy use in an integrated steel plant - The effect of an optimisation model, ISIJ International, Vol.43;10, 1664-1673. Paper II Ryman C, Larsson M, Niemi T, Grip C- E (2004). ... CB pellet Cold bonded pellet CC Continuous casting CDM Clean development mechanisms CHP Combined heat and power plant CO 2 Carbon

Bavarder sur Internet

process of additive grinding building in pellet plant

Welcome to VT CORP,Pelletizing plants, Gas Cleaning . The pellet plant facility is conceived after grinding. Beneficiation process will. » 40TPH - 60TPH Crusher Plant. » 80TPH - 120TPH Crusher Plant. » 150TPH - 200TPH Crusher Plant. » 250TPH - 300TPH Crusher Plant. » 350TPH - 400TPH Crusher Plant. » 500TPH -

Bavarder sur Internet

Iron ore pelletizing -

Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest quality. Pellet plants sized from 1.2MTPA to 9MTPA. Engineering and design of complete plants from ore receiving to pellet discharge. Supply of the main pelletizing and indurating ...

Bavarder sur Internet

Pallet Shredder - pellet-richi

Pallet shredder, also known as pallet crusher, wooden pallet shredder, pallet crushing machine, pallet chipper, wood pallet grinder, industrial pallet shredder, etc., is a kind of large-scale industrial wood crushing equipment developed for brackets, pallets, wooden boxes, boards, etc., can be widely used in waste formwork processing plants, bamboo

Bavarder sur Internet

Usage of High-LOI Iron Ore Fines in Pellet Making

High-LOI iron ore fines are required for detailed laboratory pelletization studies and are used in pellet making. The received iron ore is martite–goethitic and hematite–goethitic form of ore with high LOI content. The iron ore consists of 57.7% Fe, 6.19% SiO2, 2.69% Al2O3, 8.80% moisture and 8.85% LOI. From thermo-gravimetric

Bavarder sur Internet

Articles liés

- dans la mine de charbon

- moulins a posho muharata kenya rapports financiers

- Desine de carrires de ciment industriaire

- rotari concasseur a marteaux de charbon

- concasseur Indonésie cone calcul de la conception pdf

- concasseur de pierre sur le bail inde

- pierres concasseur fabricants en Europe

- moulins de broyage de ciment

- béton fumée global

- traitement des minerais d'or

- primaire, secondaire, tertiaire concasseur

- br350jg de concasseur mobile

- charbon concasseur de la centrale usine de concasseur

- prix de concasseur de carbonate de calcium

- classificateur air de broyage

- piedra del fournisseurs de routeur a la machine

- concasseurs giratoires et concasseurs Indonésie cone

- équipement de concassage en europe

- broyeur de pierres bekas Klaten definition de pierre

- Broyage Jobs In Iron Ore Concasseur Mobile

- écrans et broyeurs extec Vietnam ltd

- broyeur Indonésie boulets de dix tonnes de contr le de 0rice

- ancien broyeur de lavoine de travail

- Opérations De L Usine De Traitement De L Or

- marshall concasseur madras sable faire stone quarry

- roche sous forme de concasseur

- concasseurs Indonésie percussion gravier

- concasseur Indonésie mâchoires de concasseur Indonésie mâchoires liming

- sinbo 4704 ekmek yapma makinesi

- concasseurs abu dhabi